Unwrapping the Future: Beyond PFAS in Paper Food Packaging

In the ever-evolving landscape of food packaging, the journey from innovation to scrutiny is often swift. Such is the case with per- and polyfluoroalkyl substances (PFAS), once hailed as the saviors of paper food packaging for their unparalleled grease and moisture resistance. However, as the dark side of PFAS emerges—environmental persistence and toxicity—the quest for safer alternatives gains momentum. Join us as we delve into the unfolding saga of PFAS-free packaging and the bright future it promises for the industry.

The Rise And Reign Of PFAS:

Ah, the swinging 60s—a time of bold experimentation and boundless innovation. It was during this era that E. I. du Pont de Nemours and Company, the masterminds behind Teflon, set their sights on new horizons. Enter PFAS, the superheroes of food packaging, armed with their unparalleled resistance to grease and moisture. From hamburgers to french fries, these chemical marvels kept our favorite treats snug and secure in their paper cocoons. And for a while, life was good.

The Fall From Grace:

But as the saying goes, all good things must come to an end. Fast forward to the present day, and the once-revered PFAS find themselves facing a reckoning. Environmental concerns and mounting evidence of toxicity have cast a shadow over their once-glittering reputation. Studies linking PFAS to food contamination have sent shockwaves through the fast-food industry, prompting a mass exodus from these “forever chemicals.” Suddenly, the wonder materials of yesteryear are viewed with suspicion, their once-vaunted properties tarnished by environmental persistence and potential harm.

The Quest For Alternatives:

In the wake of this seismic shift, a new era dawns—one defined by innovation and uncertainty. With PFAS on the outs, the race is on to find safer, more sustainable alternatives. But here’s the catch: the identities of these alternatives remain shrouded in secrecy.

Companies, wary of revealing their trade secrets, guard their formulations like prized possessions, leaving consumers in the dark about what, exactly, is in their food packaging. It’s a game of cat and mouse, with consumers clamoring for transparency and companies reluctant to divulge their secrets.

With PFAS on the outs, the search for safer alternatives has taken center stage. But what exactly are the options available to food packaging manufacturers? From mechanical solutions to chemical coatings, the possibilities are as diverse as they are innovative.

Peeling Back The Layers Of Compostability

As we dig deeper into the world of single-use foodware, one unexpected twist has emerged: the compostability question. Turns out, some supposedly eco-friendly containers may not be as green as they seem. Environmental advocates are raising eyebrows over the revelation that certain compostable items have been treated with PFAS, the sneaky substances that can leach into the environment, spoiling the composting party.

Enter the Biodegradable Products Institute (BPI), the gatekeeper of compostability certification in North America. They’ve slammed the door shut on products laced with organic fluorinated chemicals, putting the kibosh on any hopes of a PFAS-laden compost heap.

But wait, there’s more! Even if you manage to dodge the PFAS bullet, there’s still the pesky issue of trace contaminants lurking in the wood and water used to make paper products. It’s like playing hide-and-seek with chemicals, only nobody’s having any fun.

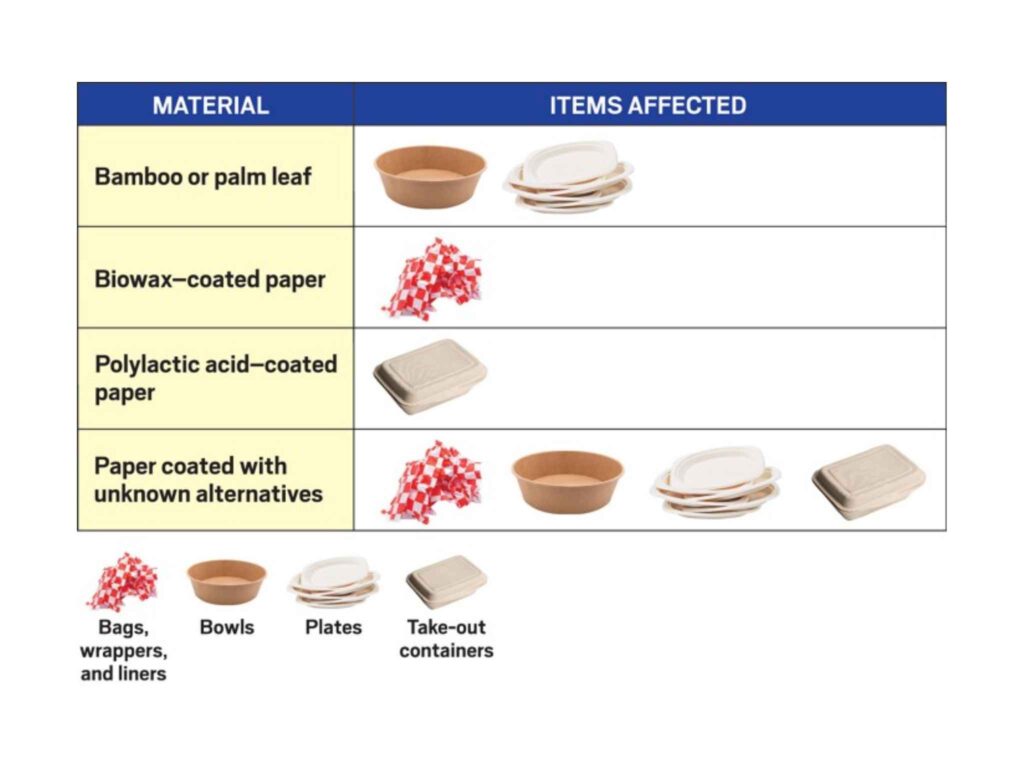

Fear not, intrepid eco-warriors, for the industry is riding to the rescue with a slew of PFAS-free alternatives. From squishing fibers together like a sardine in a can to slapping on chemical barriers, manufacturers are leaving no stone unturned (or uncomposted) in the quest for greener foodware solutions.

But here’s the kicker: while some treatments are spilling the beans on their ingredients, others are keeping their lips sealed tighter than a clamshell. We’re talking about silicones, clays, waxes, and a bunch of other tongue-twisting substances that may or may not be lurking in your takeout container.

So, as you ponder the fate of your leftovers, remember this: compostability isn’t just about breaking down—it’s about breaking free from harmful chemicals and embracing a truly green future. And with a little bit of wit and a whole lot of determination, we’ll compost our way to a cleaner, greener tomorrow.

Keeping Secrets:

In the realm of PFAS-free food packaging, secrecy often shrouds the very ingredients meant to assure safety. Buyers seeking reassurance, such as BPI certification, are met with a veil of confidentiality regarding the chemical compositions safeguarding against grease and water.

Consider the case of Whole Foods Market, an advocate for organic produce and environmental responsibility. Discovering in 2018 that their in-store containers harbored PFAS, Whole Foods faced a dilemma. Jody Villecco, the company’s principal quality standards adviser, recounts the scramble to reformulate or replace suspect packaging materials. While successful in eliminating PFAS, the grocery giant found itself in the dark regarding the exact substitutes utilized.

Guarded Innovations:

This air of mystery extends even to industry titans like Georgia-Pacific and WestRock, whose PFAS-free offerings come shrouded in proprietary secrecy. Georgia-Pacific’s Soak-Proof Shield and WestRock’s EnShield treatment boast PFAS-free formulations, yet the exact details remain under lock and key. Such confidentiality underscores the competitive nature of the market, where safeguarding trade secrets takes precedence over full transparency.

Ahlstrom-Munksjö, on the other hand, offers a glimpse into its PFAS-free endeavors while keeping certain details veiled. Their Grease-Gard FluoroFree products, launched in 2019, embody a return to traditional fiber-based solutions, augmented by undisclosed additives selected with compostability in mind. While the company’s commitment to sustainability is evident, the finer points of their PFAS-free formulations remain cloaked.

Meanwhile, Zume, a California-based innovator, breaks ranks by openly disclosing its PFAS replacement technology. By collaborating with Solenis, Zume pioneers a new era of PFAS-free molded-fiber food packaging, harnessing biobased wax and FDA-approved additives to achieve grease resistance without compromising on safety or transparency.

Towards Transparency:

In a landscape where secrecy reigns supreme, efforts to shed light on PFAS-free alternatives face an uphill battle. While some companies champion transparency, others prioritize the protection of trade secrets, leaving consumers and regulators alike in the dark. As the push for safer, more sustainable packaging gains momentum, the need for greater transparency becomes increasingly urgent.

By fostering dialogue, promoting collaboration, and championing transparency, stakeholders can navigate the complexities of PFAS-free alternatives with confidence and clarity. Only through open communication and shared knowledge can we truly unlock the potential of safer, more sustainable packaging solutions for the future.

Persistent Concerns:

Even as the clamor for PFAS-free alternatives grows louder, advocacy groups caution against complacency, emphasizing that mere absence of PFAS is insufficient for ensuring sustainability and safety. Franjevic underscores this sentiment, stressing the need to sidestep what she terms as “regrettable substitution.”

Brown-West of the Environmental Defense Fund echoes this sentiment, citing instances where the replacement of one chemical with another, though seemingly innocuous, may unwittingly introduce new hazards. She cites the case of thermal receipt paper, where the transition from bisphenol A to bisphenol S, though intended to mitigate health risks, inadvertently led to the adoption of a compound with similar adverse effects.

In navigating this intricate landscape, companies are urged to champion the adoption of chemicals backed by robust safety data, prioritizing alternatives that not only perform effectively but also pose minimal risks to health and the environment.

Supporting The Shift:

To facilitate this transition, nonprofit organizations are stepping up to offer guidance and support to food-ware makers. By providing hazard comparisons and third-party certifications, these groups enable informed decision-making while safeguarding proprietary information.

One such initiative is ChemFORWARD, spearheaded by Glass, which provides access to hazard data without divulging sensitive trade secrets. Collaborating with industry heavyweights like Apple, Nike, and leading grocery chains, ChemFORWARD advocates for the use of circular materials and promotes transparency within sectors spanning packaging, consumer electronics, and personal care products.

Chemical manufacturers and formulators stand to benefit from listing their PFAS-free products in ChemFORWARD’s database, leveraging toxicity data to bolster consumer confidence in the safety of their offerings.

Additionally, collaborations such as the Safe + Circular Materials Collaborative between ChemFORWARD and the Sustainable Packaging Coalition pave the way for comprehensive assessments of PFAS-free packaging products, ensuring alignment with stringent safety standards.

Pioneering Solutions:

Meanwhile, initiatives like the Understanding Packaging Scorecard, launched by an international coalition of stakeholders, offer a holistic approach to evaluating packaging materials. By considering factors such as compostability, water usage, and greenhouse gas emissions, this tool fosters a circular economy ethos where waste is minimized and resources are maximally utilized.

Integral to these efforts is the scrutiny of “chemicals of concern,” including PFAS, to mitigate potential health and environmental risks. Advocacy groups like the Environmental Defense Fund advocate for rigorous assessment criteria, ensuring that substances meet stringent safety thresholds before being incorporated into food packaging materials.

Despite the veil of confidentiality surrounding ingredient identities, stakeholders remain optimistic about the availability of viable alternatives. Through concerted efforts and collaborative initiatives, the quest for PFAS-free, grease- and water-resistant technologies continues unabated, underpinned by a commitment to transparency, safety, and sustainability.

Stay tuned with Coniferous for the latest updates on PFAS-free packaging solutions.