Unveiling The Mystique Of Chemical- Thermal Mechanical Pulp

This content is being republished with the consent of Fisher International and ResourceWise. Read more about Chemical-Thermal Mechanical Pulp in India at ResourceWise. June 10’23

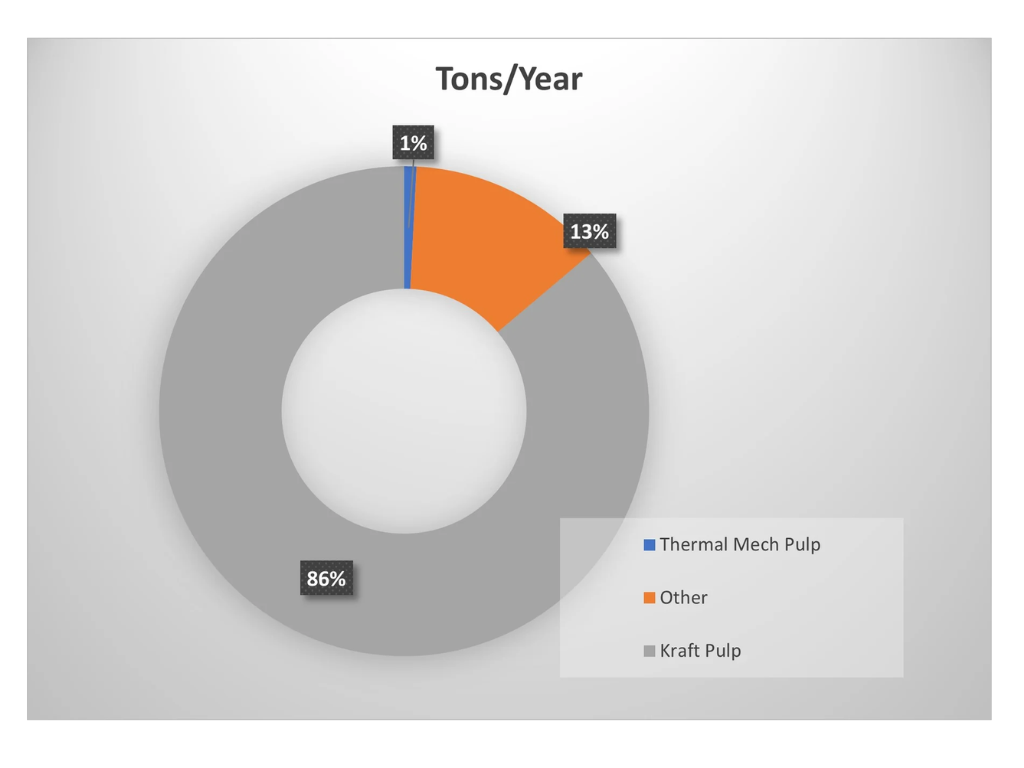

In the world of paper production, seasoned paper makers understand that a fiber blend can enhance machine runnability and improve paper quality. However, factors like fiber availability, pricing, and commercial terms often complicate the choice of pulp mix. Among various options, Chemical-Thermal Mechanical Pulp (CTMP) and similar materials stand out as the preferred fiber types for pulp producers due to their significant wood-to-pulp yield ratio when compared to kraft pulp.

Exploring Untapped Potential: Surprisingly, despite the market’s acceptance of such fibers, the global utilization of CTMP remains nearly zero. This intriguing scenario begs the question: Why is this the case? The answer lies in its price.

CTMP is known for its energy-intensive nature, resulting in considerably higher costs compared to other pulp types. As energy usage regulations become more stringent, the price gap between CTMP and alternative pulps widens. Consequently, many consider the cost burden of CTMP to outweigh its benefits.

Seizing New Opportunities:

Nevertheless, some integrated paper producers have recognized the potential advantages of CTMP and have embarked on new projects to expand its capacity, despite the higher energy costs involved. For instance, SCA recently decided to increase its CTMP production from 90,000 to 300,000 tons at its Ortviken site.

This shift in favor of CTMP is further motivated by technological advancements and improved processes in kraft lines, which have resulted in surplus energy. These developments make producing CTMP more feasible and attractive, considering its energy-intensive nature.

Use of Pulp in the Global Marketplace

©[2023] Fisher International (ResourceWise). All rights reserved.

Strategic Considerations for Mills: In light of these developments, mills must weigh several options from a strategic standpoint:

1. Selling the surplus energy in the market?

2. Investing in new integrated paper machines to consume the excess energy?

3. Producing CTMP to increase yield and save wood? 4. Selling tall oil instead of burning it?

Unleashing the Potential: For market pulp producers, it is vital to thoroughly analyze and evaluate the advantages of all available options. Dismissing the opportunity to pivot towards producing a desirable and advantageous grade within a mill due to a lack of insight into the bigger picture can lead to missed opportunities.

Before ruling out any option, it is crucial to gather accurate and comprehensive data. This ensures a better understanding of which direction aligns best with the mill’s objectives.

Let’s embark on this extraordinary adventure armed with wisdom and a touch of wit. Together, we can unleash the true potential of CTMP, tapping into its alluring qualities and making a resounding impact on the world of paper —the Coniferous way.