10 different types of packaging products

The packaging industry uses a wide range of raw materials to produce packages that not only look good but keep the product that’s inside it safe. Different types of packaging products come in different forms, with each having its own applications, along with its set of pros and cons.

Here, we will break down the plethora of packaging material for you, giving you an insight into what each entails:

Types of Packaging Products

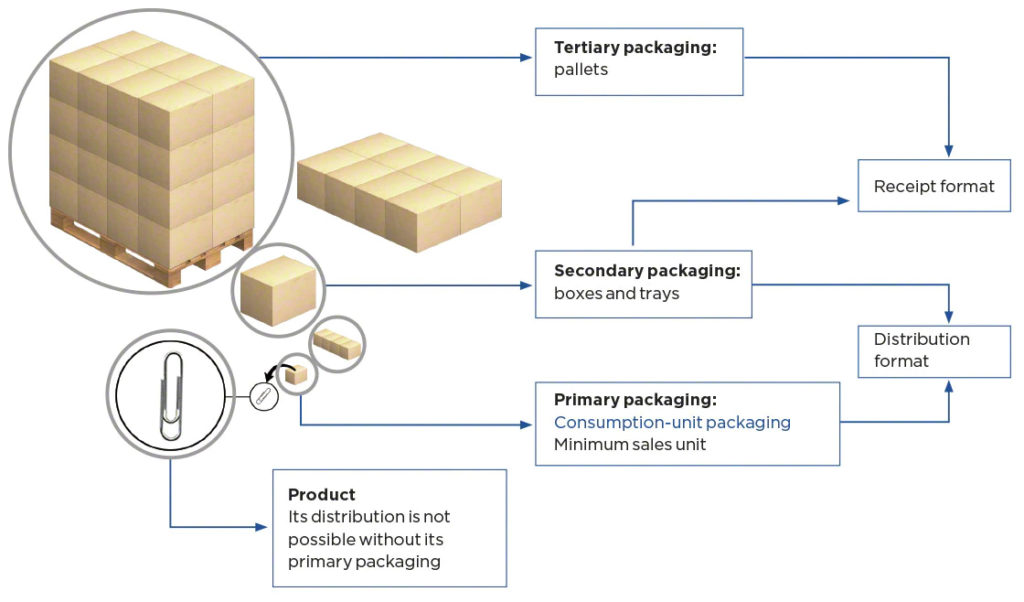

- Primary Packaging: This basically consists of products that directly come in contact with the actual product- food, accessories, clothing, gadgets.

It consists of all the packaging products included in retail packaging, food packaging, as well as void fill options, that end users have seen and used.

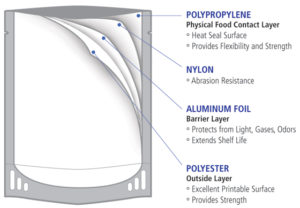

It consists of all the packaging products included in retail packaging, food packaging, as well as void fill options, that end users have seen and used. - Laminated pouches: It is one of the most commonly used types of packaging .They are bags made from polymer sheets or metallized plastic sheets that have an extra layer of laminating plastic on top of them. These pouches provide extra durability, in comparison to regular plastic bags. They are available inmultiple forms, such as zip pouches,

stand up pouches, or as regular mailers. Laminated pouches are also highly customizable as the inner layercan be printed in full colour. The external lamination ensures that the print does not wear easily, which makes them a perfect fit for retail packaging of goods.

stand up pouches, or as regular mailers. Laminated pouches are also highly customizable as the inner layercan be printed in full colour. The external lamination ensures that the print does not wear easily, which makes them a perfect fit for retail packaging of goods. - Plastic containers: This types of packaging includes a wide range of conta

iners made from high-density polyethene. Plastic containers include everything from plastic bottles, to disposable food containers, to reusable containers. These containers are widely used because they are cheap, resistant to chemical corrosion, physical wear and tear, and are also recyclable and reusable. Plastic containers can be bulk produced by injection moulding. These containers are very commonly used for food packaging, packaging medicine, oil and lubricants, chemicals, and beverages.

iners made from high-density polyethene. Plastic containers include everything from plastic bottles, to disposable food containers, to reusable containers. These containers are widely used because they are cheap, resistant to chemical corrosion, physical wear and tear, and are also recyclable and reusable. Plastic containers can be bulk produced by injection moulding. These containers are very commonly used for food packaging, packaging medicine, oil and lubricants, chemicals, and beverages.

- Thermoformed products: It is one of the recent types of packaging that came into the limelight. Thermoforming is a process in which plastic sheets are heated to a tempe

rature where they become soft and can be moulded or trimmed easily. Heated plastic is first stamped into shape and then the individual stamped pieces are trimmed. Plastics that are used in the thermoforming process are called thermoplastics. Thermoformed products include plastic containers, such as meat trays, egg trays, disposable food containers and blister packaging.

rature where they become soft and can be moulded or trimmed easily. Heated plastic is first stamped into shape and then the individual stamped pieces are trimmed. Plastics that are used in the thermoforming process are called thermoplastics. Thermoformed products include plastic containers, such as meat trays, egg trays, disposable food containers and blister packaging. - Parchment paper: It is a cellulose-based paper that is commonly used in baking. This is also known as baking paper or bakery paper. Parchment paper is manufactured by paper manufacturers using a process that is similar to tracing paper.

Modern parchment paper is made from paper pulp processed using sulphuric acid. Parchment paper has high density, heat resistance and non-stick properties. Parchment paper eliminates the need to grease sheet pans. This allows batches of baked goods to be turned around very quickly. Parchment paper is also used in other cooking processes that involve steaming the food in pouches of parchment paper.

Modern parchment paper is made from paper pulp processed using sulphuric acid. Parchment paper has high density, heat resistance and non-stick properties. Parchment paper eliminates the need to grease sheet pans. This allows batches of baked goods to be turned around very quickly. Parchment paper is also used in other cooking processes that involve steaming the food in pouches of parchment paper. - Wet strength paper: It is the most commonly used types of packaging. The wet strength of the paper is how much resistance

the paper is to rupturing once the paper is wet. Wet strength paper is a type of paper that has high resistance to being ruptured or torn when it is wet. Wet strength paper can be printed and customized just like normal Kraft paper, is biodegradable, and provides a varying degree of wet strength. Wet strength paper is commonly used to make lawn and leaf bags that are ideal for disposing of yard waste.

the paper is to rupturing once the paper is wet. Wet strength paper is a type of paper that has high resistance to being ruptured or torn when it is wet. Wet strength paper can be printed and customized just like normal Kraft paper, is biodegradable, and provides a varying degree of wet strength. Wet strength paper is commonly used to make lawn and leaf bags that are ideal for disposing of yard waste. - Monocartons: They are simple boxes that a

re made from paperboards. Mono cartons is one of the major types of packaging that are often used as retail boxes as they can be easily printed, laminated and customized. They also offer protection from minor splashes, drops and bumps.

re made from paperboards. Mono cartons is one of the major types of packaging that are often used as retail boxes as they can be easily printed, laminated and customized. They also offer protection from minor splashes, drops and bumps. - Retort pouches: A type of food packaging, made from metallized

plastics. Metal foils are laminated using plastics that offer the rigidity of metals as well as the corrosion resistance of plastics. These provide sterile food packaging that is an alternative to tin cans. Retort pouches are used to pack high caloric, fully cooked, frozen MREs (Meals, Ready to Eat). Retort pouches can withstand high temperatures and the food can be cooked right inside the pouch with the package sealed. Retort pouches are also used to pack other raw food items. Some variants of retort pouches have a bottom gusset and are called a stand-up retort pouch.

plastics. Metal foils are laminated using plastics that offer the rigidity of metals as well as the corrosion resistance of plastics. These provide sterile food packaging that is an alternative to tin cans. Retort pouches are used to pack high caloric, fully cooked, frozen MREs (Meals, Ready to Eat). Retort pouches can withstand high temperatures and the food can be cooked right inside the pouch with the package sealed. Retort pouches are also used to pack other raw food items. Some variants of retort pouches have a bottom gusset and are called a stand-up retort pouch. - Paper-foil laminate: It is paper laminated with aluminium foil.

The paper and the foil have complimentary properties that make the paper foil laminate a durable and low-cost packaging material. This metallized paper types of packaging is often used to make paper plates, recyclable food packaging, wrappers for chocolates and other food products. Paper foil laminates are also laminated with plastic layers to improve their barrier properties and to improve the wet strength of the sheets. These make stronger pouches for wet food products, such as sauces and pickles.

The paper and the foil have complimentary properties that make the paper foil laminate a durable and low-cost packaging material. This metallized paper types of packaging is often used to make paper plates, recyclable food packaging, wrappers for chocolates and other food products. Paper foil laminates are also laminated with plastic layers to improve their barrier properties and to improve the wet strength of the sheets. These make stronger pouches for wet food products, such as sauces and pickles. - Composite cans: These are made from multiple layers that provide rigidity and

certain barrier properties. Composite cans are made from paper, paper boards, aluminium foils and plastic laminates. This makes them ideal for food packaging. The packaging used for Pringles are composite cans. Other similar dry food items, such as biscuits, health drink malts, and tea leaves are packed using composite cans too. Composite cans are used as an exterior protective covering for glass bottles containing drinks.

certain barrier properties. Composite cans are made from paper, paper boards, aluminium foils and plastic laminates. This makes them ideal for food packaging. The packaging used for Pringles are composite cans. Other similar dry food items, such as biscuits, health drink malts, and tea leaves are packed using composite cans too. Composite cans are used as an exterior protective covering for glass bottles containing drinks.

Whilst there are various other forms of packaging including Secondary, Tertiary, and other types of Primary packaging. The above 10 like medical and food packaging are the most common types of primary packaging that we encounter! Ultimately the goal of good packaging is to transport and preserve goods safely till their final utilization, minimizing wastage. Whilst nowadays packaging is also used as a medium to advertise the USP of the product!

It consists of all the packaging products included in retail packaging, food packaging, as well as void fill options, that end users have seen and used.

It consists of all the packaging products included in retail packaging, food packaging, as well as void fill options, that end users have seen and used. stand up pouches, or as regular mailers. Laminated pouches are also highly customizable as the inner layercan be printed in full colour. The external lamination ensures that the print does not wear easily, which makes them a perfect fit for retail packaging of goods.

stand up pouches, or as regular mailers. Laminated pouches are also highly customizable as the inner layercan be printed in full colour. The external lamination ensures that the print does not wear easily, which makes them a perfect fit for retail packaging of goods. iners made from high-density polyethene. Plastic containers include everything from plastic bottles, to disposable food containers, to reusable containers. These containers are widely used because they are cheap, resistant to chemical corrosion, physical wear and tear, and are also recyclable and reusable. Plastic containers can be bulk produced by injection moulding. These containers are very commonly used for food packaging, packaging medicine, oil and lubricants, chemicals, and beverages.

iners made from high-density polyethene. Plastic containers include everything from plastic bottles, to disposable food containers, to reusable containers. These containers are widely used because they are cheap, resistant to chemical corrosion, physical wear and tear, and are also recyclable and reusable. Plastic containers can be bulk produced by injection moulding. These containers are very commonly used for food packaging, packaging medicine, oil and lubricants, chemicals, and beverages. rature where they become soft and can be moulded or trimmed easily. Heated plastic is first stamped into shape and then the individual stamped pieces are trimmed. Plastics that are used in the thermoforming process are called thermoplastics. Thermoformed products include plastic containers, such as meat trays, egg trays, disposable food containers and blister packaging.

rature where they become soft and can be moulded or trimmed easily. Heated plastic is first stamped into shape and then the individual stamped pieces are trimmed. Plastics that are used in the thermoforming process are called thermoplastics. Thermoformed products include plastic containers, such as meat trays, egg trays, disposable food containers and blister packaging. Modern parchment paper is made from paper pulp processed using sulphuric acid. Parchment paper has high density, heat resistance and non-stick properties. Parchment paper eliminates the need to grease sheet pans. This allows batches of baked goods to be turned around very quickly. Parchment paper is also used in other cooking processes that involve steaming the food in pouches of parchment paper.

Modern parchment paper is made from paper pulp processed using sulphuric acid. Parchment paper has high density, heat resistance and non-stick properties. Parchment paper eliminates the need to grease sheet pans. This allows batches of baked goods to be turned around very quickly. Parchment paper is also used in other cooking processes that involve steaming the food in pouches of parchment paper. the paper is to rupturing once the paper is wet. Wet strength paper is a type of paper that has high resistance to being ruptured or torn when it is wet. Wet strength paper can be printed and customized just like normal Kraft paper, is biodegradable, and provides a varying degree of wet strength. Wet strength paper is commonly used to make lawn and leaf bags that are ideal for disposing of yard waste.

the paper is to rupturing once the paper is wet. Wet strength paper is a type of paper that has high resistance to being ruptured or torn when it is wet. Wet strength paper can be printed and customized just like normal Kraft paper, is biodegradable, and provides a varying degree of wet strength. Wet strength paper is commonly used to make lawn and leaf bags that are ideal for disposing of yard waste. re made from paperboards.

re made from paperboards.  plastics. Metal foils are laminated using plastics that offer the rigidity of metals as well as the corrosion resistance of plastics. These provide sterile food packaging that is an alternative to tin cans. Retort pouches are used to pack high caloric, fully cooked, frozen MREs (Meals, Ready to Eat). Retort pouches can withstand high temperatures and the food can be cooked right inside the pouch with the package sealed. Retort pouches are also used to pack other raw food items. Some variants of retort pouches have a bottom gusset and are called a stand-up retort pouch.

plastics. Metal foils are laminated using plastics that offer the rigidity of metals as well as the corrosion resistance of plastics. These provide sterile food packaging that is an alternative to tin cans. Retort pouches are used to pack high caloric, fully cooked, frozen MREs (Meals, Ready to Eat). Retort pouches can withstand high temperatures and the food can be cooked right inside the pouch with the package sealed. Retort pouches are also used to pack other raw food items. Some variants of retort pouches have a bottom gusset and are called a stand-up retort pouch. The paper and the foil have complimentary properties that make the paper foil laminate a durable and low-cost packaging material. This metallized paper types of packaging is often used to make paper plates, recyclable food packaging, wrappers for chocolates and other food products. Paper foil laminates are also laminated with plastic layers to improve their barrier properties and to improve the wet strength of the sheets. These make stronger pouches for wet food products, such as sauces and pickles.

The paper and the foil have complimentary properties that make the paper foil laminate a durable and low-cost packaging material. This metallized paper types of packaging is often used to make paper plates, recyclable food packaging, wrappers for chocolates and other food products. Paper foil laminates are also laminated with plastic layers to improve their barrier properties and to improve the wet strength of the sheets. These make stronger pouches for wet food products, such as sauces and pickles. certain barrier properties. Composite cans are made from paper, paper boards, aluminium foils and plastic laminates. This makes them ideal for food packaging. The packaging used for Pringles are composite cans. Other similar dry food items, such as biscuits, health drink malts, and tea leaves are packed using composite cans too. Composite cans are used as an exterior protective covering for glass bottles containing drinks.

certain barrier properties. Composite cans are made from paper, paper boards, aluminium foils and plastic laminates. This makes them ideal for food packaging. The packaging used for Pringles are composite cans. Other similar dry food items, such as biscuits, health drink malts, and tea leaves are packed using composite cans too. Composite cans are used as an exterior protective covering for glass bottles containing drinks.