How to improve Tissue Sheet Softness?

Softness vs Strength

In tissue sheet and towel grades, softness and strength are often regarded as the two most essential customer qualities. Softness should be enhanced to improve the product’s customer impression, yet strength must be maintained to ensure that the product functions well throughout usage. Regrettably, softness and strength have a well-known inverse connection. Strength diminishes as softness grows, or put another way, as strength levels increase, softness decreases.

Definition of softness

The consumer’s sense of softness is the result of a complicated interaction with the product that is impacted by the tissue sheet’s physical and sensory qualities.

Tissue paper softness is divided into two categories:

- Bulk softness

- Surface softness

Bulk softness is measured by gently squishing or crumpling of the tissue, and it is inversely proportional to flexural rigidity or stiffness. The delicate stroking of the fingers over the tissue sheet surface is used to measure surface softness. It has to do with the tissue’s smoothness, texture, and surface homogeneity.

Evaluating softness

Because softness is the key predictor of customer preference in categories like shower and facial tissue, tissue makers need a way to analyze or grade the softness of their own and competing goods. Subjective panel tests, which consist of assigning an independent softness value to a specific tissue sample, generally in reference to a specification, are the most often used approach for evaluating softness.

Instrumental methods have been studied and refined throughout the years in order to make softness testing easier, faster, and more accurate. Bulk and surface softness may both be evaluated using different methods. However, these individual data can then be used to estimate a panel softness value using a user-developed algorithm.

The bulk softness can be measured using one or ideally a combination of well-known tools for assessing stiffness, bending resistance, and/or flexural rigidity with a relatively simple approach.

Surface softness is harder to measure since numerous subjective physiologic and perceptual elements influence this impression. Tissue paper’s surface touch feel may be described using two comparisons of different sorts of textile fabrics like forming fabric. In the first scenario, increasing the amount of projecting free fiber ends from the tissue’s surface can improve the surface feeling. This is known as a flannel-type surface. In the second scenario, improving the surface’s smoothness and/or lubricity can likewise improve the touch feel. This is known as a silk-like surface.

Factors affecting softness:

During the tissue-making process, hundreds of various factors might affect softness. Here are a few examples.

- Fibre Furnish

- Stratification/Layering

- Formation

- Manufacturing process

- Pressing

- Calendering

- Creping

Chemical Softening of Tissue Sheet:

Chemical techniques are another possible way to produce the necessary softness, depending on parameters such as the fibres used, the mechanical design of the paper machine and its components, and operational variables. Main methods include

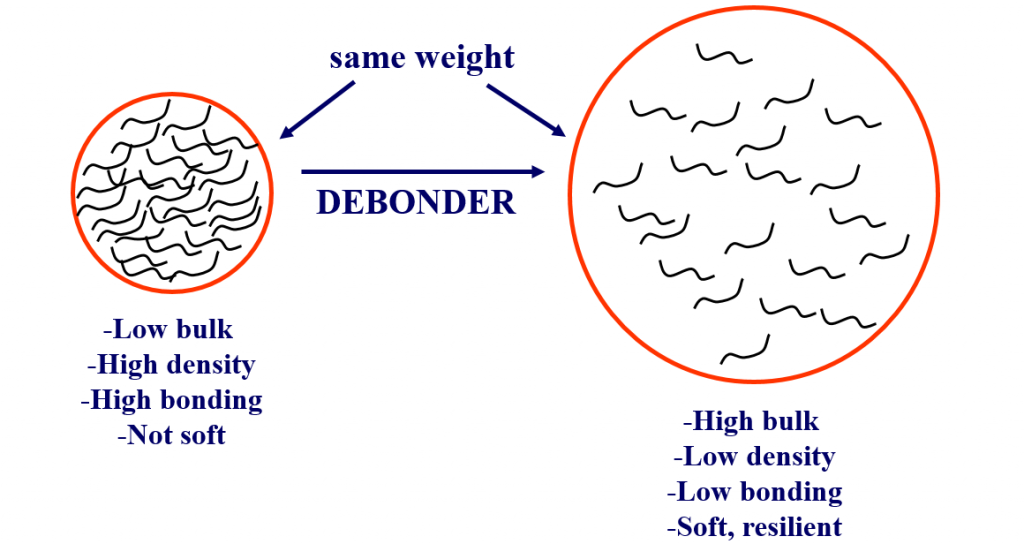

Debonders

Softeners

Lotions

Tissue sheet softness and how to enhance it is a complicated topic. This first overview is intended to provide the reader with a basic understanding of the subject. Because softness is such an essential end-use attribute of tissue, manufacturers and their paper suppliers are always working to enhance strength-softness qualities through advancements in raw resources, mechanical design, and operational circumstances.