Overview

Logistics is a critical part of any supply chain including the paper supply chain. In fact at our parent company, we believe that logistics makes up a critical part of the sustainability of the product. Logistics is just not shipping! It is more than that! If the mill is very far from the place of final consumption, the logistical cost will make the product unviable, or the customer would have to work on sleeker margin. Also there will be a lot more carbon emission to get the material there! There by even if you are using the best environmental practices at your plant, are you truly sustainable.

Logistics is the detailed organization and implementation of a complex organization. In our industry logistics can be broken into three main parts:

As converters or consumers of the finished form of the paper or board we use, we believe that we should only be bothered about the part that impacts us. But what we chose to conveniently ignore is that the process is seldom independent of the previous! Our industry is tightly knit and thus every part of the process is critical and important!

If the pulp is not supplied adequately to the mill, the mill cannot convert, and if the mill does not convert what will the convertor consume, and if the convertor does not convert efficiently will he be able to supply the market aptly? Thus, it is a completely integrated process.

Since HYPA is dedicated towards the convertors and consumers, let us focus on the same. Taking the example of the tissue industry here is a general process flow of goods in the industry:

Thus to make a simple toilet roll, you can imagine where the raw material would travel from. Imagine it is not an integrated mill based in Muzaffar Nagar (A prominent paper making belt in India). The pulp might come from an Indonesian supplier to Nava Sava, from where the product is cleared and railed to ICD Moradabad and then trucked to the mill. The raw materials and chemicals are imported from China, and since these make up for 10% of the conversion, lets take the same in account for illustration. The mill has produced the paper and now we would like to reach a converter based in Okhala, which is a part National Capital Region (NCR) of India and a major converting hub. A Toilet Roll might way 100 grams, and thus would be 0.03% of the weightage again for illustrative purposes. The converter aspires to sell the same in Delhi in case 1 and in Bangalore (A major city in the south of India) as Case 2. The same is only to imply the importance of logistics. Do not take the values as definitive or factual.

| Part of the Supply Chain |

Kms. Travelled |

||

|---|---|---|---|

| Getting the pulp into Nava Seva |

5715 |

||

| From Nava Seva to ICD moradabad |

1602 |

||

| ICD moradabad to Muzaffarnagar |

143 |

||

| Getting the Raw Materials from China into Nava Seva |

9360 (10%) = 936.1 |

||

| Getting the same to ICD moradabad |

160.2 |

||

| Getting the same to the factory |

14.3 |

||

| Taking the finished rolls to the converter in okhala |

132 |

||

| Taking the converted roll to Delhi (Case 1) |

0.006 |

||

| Taking the converted roll to Bangalore (Case 2) |

0.6393 |

||

| Total |

Case 1 |

Case 2 |

|

|

8703.24 |

8703.87 |

||

What we are trying to illustrate is that there is a lot of movement of goods done to get the roll to the end destination! Sometimes pulp is local, or made from wood, etc. and there is different weightage on the distances taken. But the industry is heavily dependent on efficient movement. The slightest change in logistics can hamper the entire supply chain. Also, in the industry as we move down the supply chain though the impact of weight of the cargo reduces, as products get bulkier, but simultaneously the impact of volume and bulk impact the cost. Which is why in many parts of the worlds, water companies and FMCG distributors distribute tissue, as tissue is light and bulky, and can be used as a filler!

Supply Chain

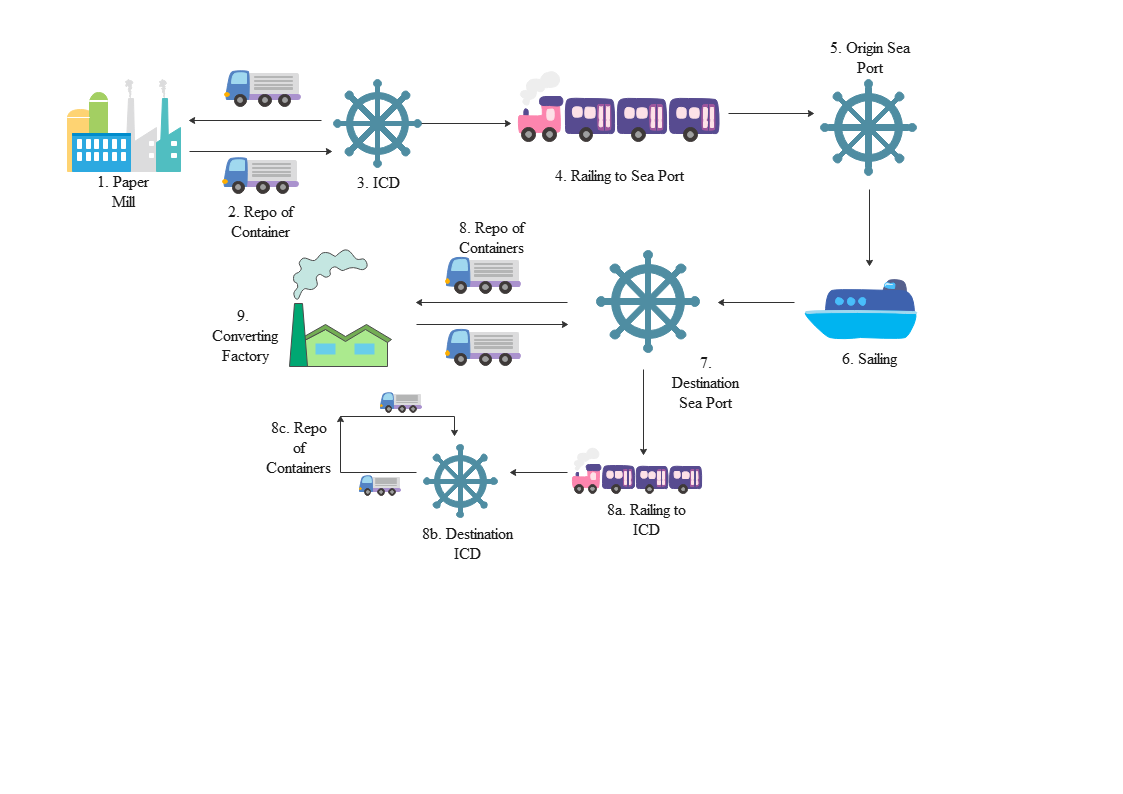

Going through the paper supply chain of taking a container of Tissue from the mill to a converting plant in brief in three instances, assuming that the converting plant is based in UAE:

Mill in India (> 350kms from a Sea Port)

- A paper mill in India with a distance in excess of 350 kms from the seaport, and having access to a nearby Inland Container Depot (ICD):

- The goods are produced at the Paper Mill

- A Commercial Invoice is generated from the mill

- A Packing List is generated stating the exact content and the weight of the goods placed in the container

- Empty containers are picked from the Inland Container Depot for stuffing in the mill and then the filled containers are returned to the Inland Container Depot.

- The container undergoes export clearance at the ICD

- The Certificate of origin (COO) is issued. The COO is issued from an international chamber of commerce stating the origin of the material

- Some shipping lines can also issue a Received for Shipment Bill of Lading (RFS BL) stating the goods have been received for shipment

- The container is railed to the Port of Loading

- The container arrives at the Port of Loading (POL) and is then placed at the terminal awaiting its turn for sailing

- The container is placed on the ship and a manifest is filed with the origin port stating contents of the ship and who the goods were sent by and who is receiving the same.

- The Shipped-on Board Bill of Lading (BL) is issued at this stage. Stating that the consignment is on board the vessel that has departed to the destination port.

- The ship arrives at the Destination port (POD) and files the manifest with the destination customs stating its content and who are the owners of the goods as well as who sent it. The customer at this stage clears the goods using the shipping documents

- Post customs clearance the customer the customer takes the good via a trailer to his warehouse and returns the empty containers back to the line.

- If the converting factory is far from the port and the country has the infrastructure to carry containers by rail, the containers are then railed to the ICD

- Post clearance the containers are emptied in the converting factory and the empty containers are returned to the ICD

- The converting mill converts the same making it into attractive consumer products

Mill in India (< 350kms from a Sea Port)

- The goods are produced at the Paper Mill

- A Commercial Invoice is generated from the mill

- A Packing List is generated stating the exact content and the weight of the goods placed in the container

- Empty containers are picked from the Port for stuffing in the mill and then the filled containers are returned to Port of Loading (POL)

- The container undergoes export clearance at the port

- The Certificate of origin (COO) is issued. The COO is issued from an international chamber of commerce stating the origin of the material

- Some shipping lines can also issue a Received for Shipment Bill of Lading (RFS BL) stating the goods have been received for shipment

- The container is placed on the ship and a manifest is filed with the origin port stating contents of the ship and who the goods were sent by and who is receiving the same.

- The Shipped-on Board Bill of Lading (BL) is issued at this stage. Stating that the consignment is on board the vessel that has departed to the destination port.

- The ship arrives at the Destination port (POD) and files the manifest with the destination customs stating its content and who are the owners of the goods as well as who sent it. The customer at this stage clears the goods using the shipping documents

- Post customs clearance the customer the customer takes the good via a trailer to his warehouse and returns the empty containers back to the line.

- If the converting factory is far from the port and the country has the infrastructure to carry containers by rail, the containers are then railed to the ICD

- Post clearance the containers are emptied in the converting factory and the empty containers are returned to the ICD

- The converting mill converts the same making it into attractive consumer products

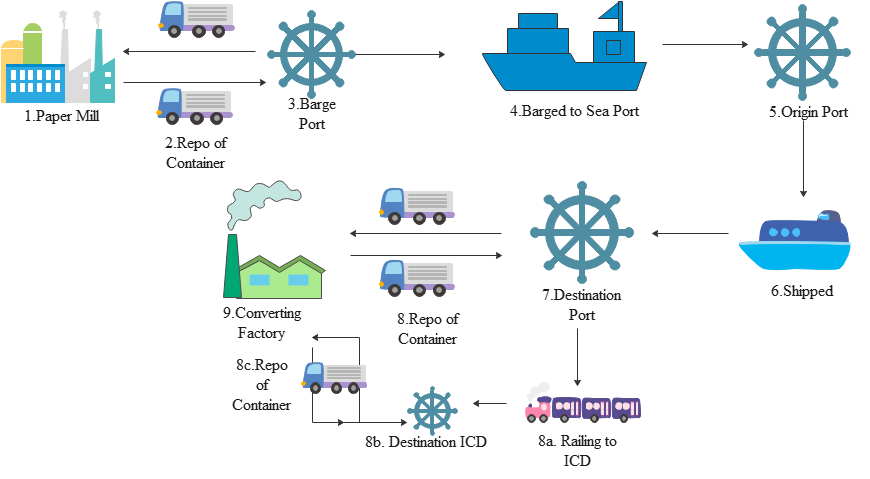

Mill in India (< 350kms from a Sea Port)

- The goods are produced at the Paper Mill

- A Commercial Invoice is generated from the mill

- A Packing List is generated stating the exact content and the weight of the goods placed in the container

- Empty containers are picked from the Barge Port for stuffing in the mill and then the filled containers are returned to barge port.

- The container arrives at the Barge Port and awaits a Barge

- Container is transported from the Barge Port to the Port of Loading (POL)

- The container arrives at the POL and post, export custom clearance the container awaits it turn shipping at the port

- The Certificate of origin (COO) is issued. The COO is issued from an international chamber of commerce stating the origin of the material

- Some shipping lines can also issue a Received for Shipment Bill of Lading (RFS BL) stating the goods have been received for shipment

- The container is placed on the ship and a manifest is filed with the origin port stating contents of the ship and who the goods were sent by and who is receiving the same.

- The Shipped-on Board Bill of Lading (BL) is issued at this stage. Stating that the consignment is on board the vessel that has departed to the destination port.

- The ship arrives at the Destination port (POD) and files the manifest with the destination customs stating its content and who are the owners of the goods as well as who sent it. The customer at this stage clears the goods using the shipping documents

- Post customs clearance the customer the customer takes the good via a trailer to his warehouse and returns the empty containers back to the line.

- If the converting factory is far from the port and the country has the infrastructure to carry containers by rail, the containers are then railed to the ICD

- Post clearance the containers are emptied in the converting factory and the empty containers are returned to the ICD

- The converting mill converts the same making it into attractive consumer products

What we are trying to illustrate from the above instance is that the supply chain of just getting the parent rolls or sheets from the mill to the printer, converting factory or the stockiest itself includes various steps and all of the same adds on to become a significant cost in the entire operation. Tissue being bulky occupies a lot of roll. In general, in a 40 ft High Cube container we can only fit in 12 – 14 MT of parent rolls depending on the size.

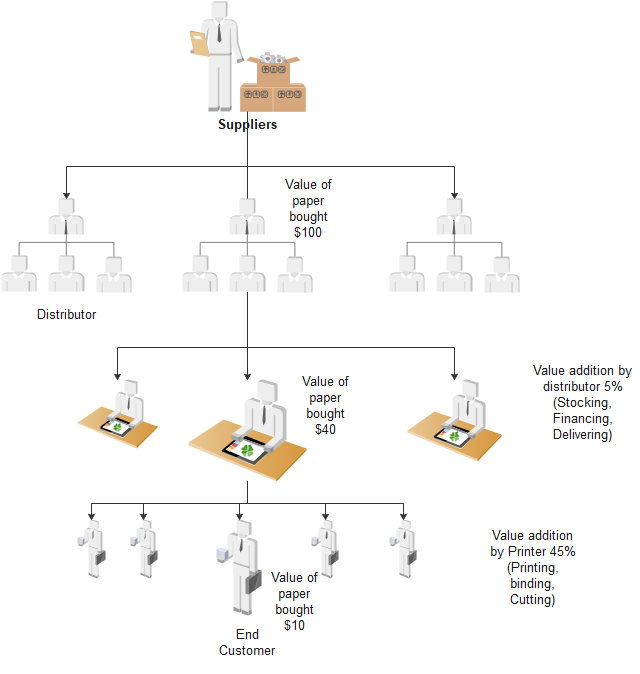

Coming down the supply chain even more, lets have a brief snap shot at how a converter distributes:

As mentioned before a convertor either supplies to commercial outlets where the consumption happens or through a retail or distribution channel where the consumer buys the products for consumption. In simpler terms for example a packet of napkin. If the customer is paying the price of the napkin for his personal consumption, it is generally considered as a retail sales, whilst if the business is procuring the napkin to enhance the experience of the customer or use it in their process it is considered as Away from Home.

Some companies have a distribution outlook where they like to sell to and interact directly with the customer either through van sales or having depot sales spread across their geographies. Whilst on the other hand, some distribute their product directly with large retail chains such as Carrefour, Big Bazar, Target, Walmart amongst others, and others might use a distributor to facilitate the same. Smaller retail shops have a much smaller requirement, for example a shop where our office is located consumes only 10 boxes of Facial Tissue per week! Thus making it practical to service the said customer through a distributor who can club and supply his requirements.

Same is the case in Industrial or Away from Home, where a distributor might be appointed to deliver and ensure financial compliance delivering in all the branches of the institution they would be servicing. Some institutions have a central warehouse where they procure and distribute amongst branches by themselves. If the consumer has a decent sized requirement, the customer also supplies him directly avoiding the costs associated with the distributors.

The above is a general and macroscopic view of the downward supply chain, with it getting more complicated and simplified based on each company’s strategy. Some only supply through e-commerce.

Usually whilst we come down the supply chain there is an addition in value to the product but also a reduction in transactional value. For example, a paper mill will supply $100 worth of paper to a distributor who might supply $40 worth of the goods to the printer. The printer then might service the end customer by $2 worth of printed goods and supply multiple such converter.