Automation in The Paper and Pulp Industry

Despite the fact that many pulp and paper mills have been automated for years, they are only now beginning to realise the full potential of digital technologies.

Automation in paper industry is the next logical step in its evolution. Newer innovations and modern technologies have enabled a sustainable future for the paper industry. The pulp and paper sector has turned to digital in recent years to improve operations. Three market dynamics are driving this: ongoing pricing pressure on papermakers as the market for conventional paper goods shrinks, increased demand for paper packaging products as a more sustainable approach to plastic, and expanding demand for tissue products worldwide.

The pulp and paper business is ripe for automation. It’s essential to understand the nature of what you’re machining, as well as your individual requirements and capabilities, before deciding on the appropriate amount of automation.

Applications of Automation in Paper Industry

Automation in paper industry can assist decrease labor costs, managing storage, tracking inventory, preventing roll damage, boosting productivity, and cutting the capital investment associated with forklift systems in numerous crucial parts of the mill. Automation in paper industry will play an increasingly important role in mill safety, efficiency, and revenue in the future.

By exploiting enormous amounts of production data to give superior insights and results, digital technologies—machine connectivity, intelligent automation, and sophisticated analytics—enable unprecedented levels of efficiency in pulp and paper operations.

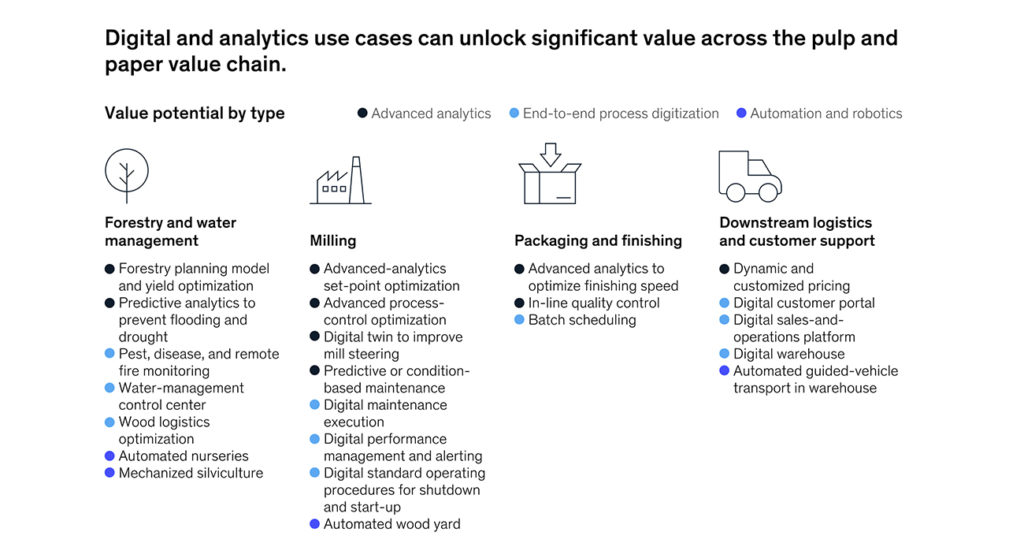

Throughput improvements of 5 to 10%, yield advances of up to 5%, and considerable material, chemical, and energy reductions are all common outcomes for successful digital innovators. This offers a $4 billion to $6 billion potential for the business, and the value may be realized right now. Across the whole pulp and paper value chain, over 25 unique use applications are currently creating value.

We see the value of applications that follow the real-time material movement from harvester to mill in forestry and logistics to assist optimize delivery and planning. Advanced analytics is being used in pulp mills to enhance kappa control and fibre production.

Energy efficiency, AI-driven root-cause issue solutions, and speed optimization all help paper mills and the paper industry increase profit per hour. Finally, better analytics is resulting in higher quality.

Companies that get the most out of their digital investments excel at three things:

- Make an effective value-capture road map and implement the appropriate technological enablers. Companies must be able to clearly describe the complete value potential of digital, as well as how they intend to extract that value over time. A strategic road map assists the company in determining the sequence of value-capture efforts as well as the technological enablers (like pressure paper sensors, data pipelines, and storage) that must be implemented in order to capitalize on the opportunity. Avoid doing technical experiments and instead manage the program to a well-defined strategic plan with specified key performance indicators (KPIs). Learn the top 10 important KPIs of the paper industry.

- Create new capabilities on your own. New talents and methods of functioning are required for successful digital transformation. Companies can augment their staff with external contractors to get started and generate momentum; nevertheless, if they want digitalization to expand and be sustained, they must establish these new competencies in-house. Companies must combine technology and data knowledge with fundamental processes and operational know-how to gain maximum value and enhance implementation success. This necessitates a strong emphasis on systematic hiring and upskilling.

- Master the art of change management. The most advanced digital solutions are useless unless they are embraced and used on a daily basis in the office. To do this, businesses must pay close attention to the technology’s end-users and devote time to learning about their needs and incorporating their input. Both teaching and reinforcing new habits, as well as installing new applications, require equal emphasis and attention.

Over the next several years, the margin between digital leading contenders and laggards is anticipated to widen, giving organizations that get their digital transitions right a substantial competitive edge. Exploring opportunities and aligning the senior management on a vision and aspiration for digital, as well as laying out a business strategy road map that deems critical business KPIs, straps the organization’s strengths, and is driven by business priorities, is a no-regrets first move for pulp & paper industry that have not yet initiated this transformation.

Also, learn more about the emerging trends in the pulp paper industry.